Bear CNC Automation

Automate your business

Automate your life

Southern California Automation and Machine Tool Engineers

About Us

Welcome to Bear CNC Automation, where we take care of all of your automation and machine tool needs.

Whether you want to start a new project or you want to retrofit an existing machine, Bear CNC Automation can cover all of your needs.

Chairman

Quoc Phan

- Bear Technology Group LLC was founded by Mr. Quoc Phan in 2008

- Later on, the company was named again to Bear CNC Automation

- 30+ years experienced in engineering

- Main office is conveniently located at Fenwick Lane, Westminster, in the middle of other manufacturing factories

- Southern California native

Why Us?

Get more than you expect

- We trade machines worldwide

- New projects are welcome upon requests

- Experienced partners

- Willing to travel to your doorstep

- Low-price guaranteed

- Wide network

What we do

Satisfy your automation needs

- Sell / Buy / Repair CNC machines

- Assist you with your project

- Manufacturing

- Contracting

- Supply outlet for various machine tools, controls, and sensors

- Offer manufacturing facilities a reliable source of controls, sensors, programming services, custom automation assemblies

- Training programs

- Preventive maintenance services to reduce maintenance costs and increase equipment availability

Shop Now

Check out our products.

Services

This is where all of your automation needs are accomplished.

Machine Tools

Bear Technology Group specializes in onsite retrofitting and rebuilding of all types of machine tool equipment.

Retrofitting with newer style PLC's and CNC controls can greatly improve the efficiency, repeatability, and accuracy of your existing equipment, but without the large capital expense of purchasing new machine tools.

We have field service professionals that can repair your tooling equipment and get you back up and running as quickly, and inexpensively, as possible. We offer preventive maintenance services, inspection, alignment, and rebuilding/retrofitting of most makes and models of machine tool equipment.

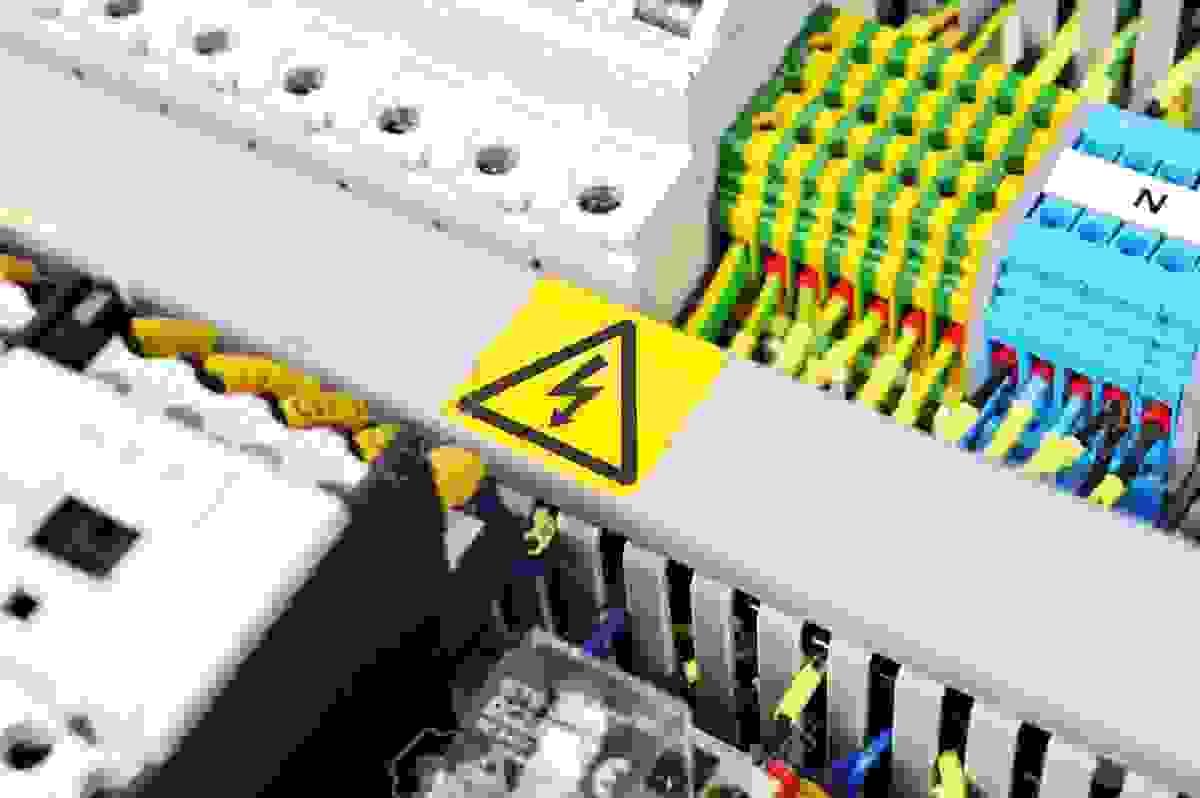

Controls & Sensors

Sensors are the mainstay in modern automated production facilities. Along with a variety of control components and programmable logic controllers (PLC's), sensors drive the process by acting as the "senses" of the production equipment. PLC's use the input from an array of sensors and convert this information, using the logic programmed into the PLC, to provide digital and analog outputs to a variety of controls.

Bear Technology Group offers a number of sensors and controls to satisfy your particular requirements. We specialize in the use of eddy current technologies for measuring a variety of physical properties with a high degree of accuracy and repeatability. These properties include overall thickness and coating thickness, surface and subsurface faults, viscoelestic properties, and many more.

The following is a partial list of sensors and contols available - most of which are availabe in both wired or wireless types

- CNC Controllers

- Proximity detecters

- Ultrasonic sensors (level & distance)

- Infrared and laser sensors

- Flow sensors

- Pressure, Temperature, & Humidity transducers

- Vibration sensors

- Load Cells

- Encoders

- eddy current

- Digital Displays

- Pnuematic & motor driven actuators and positioners

- Solenoids

- Valves

- Variable speed Drives for AC Motors

- Servo Drives & Motors

- Stepper Motors & Drivers

- Prorammble Logic Controllers

- Touch Screens

- PLC's

Programming

We are an automation and machines tools maintenance services and supply outlet for various machine tools, controls, and sensors used in the industrial automation markets. We offer manufacturing facilities a reliable source of controls, sensors, programming services, custom automation assemblies for use in automating their production processes, training programs, and preventive maintenance services to reduce maintenance costs and increase equipment availability.

Automation

We have automation and machines tools maintenance services and supply outlet for various machine tools, controls, and sensors used in the industrial automation markets. We offer manufacturing facilities a reliable source of controls, sensors, programming services, custom automation assemblies for use in automating their production processes, training programs, and preventive maintenance services to reduce maintenance costs and increase equipment availability.

Training

- PLC begining, intermediate, and advanced training services

- CNC setup, programming, and preventative maintenance training services

- Servo motors, variable frequency drives, and stepper motor controls training services

Mori Seiki Experts

�Repair

We repair equipment and sell parts when necessary, with repairs to include:

• Rebuilding Spindles

• Rebuilding Ball Screws

• Replacing Bearings

• Repairing Gear Boxes• Rebuilding Full Machines

• Replacing Machine Bedways

• Grinding

• FittingRush Repair Service is available upon request and in most cases can be completed in as little as 24 hours. Additional fees will apply for rush service.

Evaluations are free and if your Mori Seiki CNCs is beyond repair, we will do everything we can to get you a replacement. For a Free Evaluation, call +1-714-349-6954 for more information and help.

�Preventive Maintenance

Full-service capabilities for any brand, make, or model machine tool.

Keep your machines running at peak performance with our custom-tailored maintenance programs fit around your schedule.

Complete Machine Inspection & Care

We conduct a thorough ground-up inspection and deep cleaning to cover all critical aspects of your CNC machine, including but not limited to: way lube replacement, hydraulic fluid replacement, wipers, ways, way covers, airlines, lube lines, filters, chillers, hydraulic hoses, motors, spindles, ball screws, gearboxes, drives, power tracks, tool changers, chip conveyors, controls, and more.

Machine Decommissioning

Organized and careful disassembly of existing machines for transfer, resale, or relocation.

Machine Recommissioning

Installation, set-up, and leveling of new or used machines.

Field Service

We come to where your machines are and bring all the necessary tools and equipment, across North America.

Training

The training program will be custom-made for your specific needs with hands-on experience. Whether you are a student with little experience who wishes to land an entry-level position in engineering or an employer who wishes to train your staff, we provide all the necessary knowledge to operate machines.

CNC machine repair near me , CNC maintenance services, Industrial CNC machine servicing , Affordable CNC machine repair , mori seiki repair near me, 4/7 CNC machine servicing in southern california, 4/7 CNC machine servicing in orange county, Professional CNC Machine Servicing & Repair Bear CNC Automation, best mori seiki service near me, How often should I service my CNC machine, What’s the cost of CNC machine repair, CNC Machine Servicing & Repair Services, mori seiki emergency repair, top cnc machine maintenance in southern california, top mori seiki service in orange county, CNC Machine Maintenance Checklist, cheap mori seiki service near me, Mori Seiki repair near me, Mori Seiki repair Orange County, Mori Seiki machine repair near me, Mori Seiki maintenance Orange County Mori Seiki CNC repair near meAffordable Mori Seiki repair Orange County Best Mori Seiki repair service near me Mori Seiki CNC machine repair Orange County Emergency Mori Seiki repair near me Mori Seiki spindle repair Orange County Mori Seiki lathe repair near me Mori Seiki mill repair Orange County Mori Seiki service center near me Mori Seiki repair and maintenance Orange County Mori Seiki troubleshooting and repair near me Mori Seiki repair in Santa Ana Mori Seiki repair in Anaheim Mori Seiki repair in Irvine Mori Seiki repair in Huntington Beach Mori Seiki repair in Costa Mesa Mori Seiki repair in Fullerton Mori Seiki repair in Garden Grove Mori Seiki repair in Orange Mori Seiki repair in Newport Beach Mori Seiki repair in TustinMori Seiki preventive maintenance Orange County Mori Seiki calibration services near me Mori Seiki electrical repair Orange County Mori Seiki hydraulic system repair near me Mori Seiki parts replacement Orange County Mori Seiki CNC troubleshooting near me Mori Seiki retrofit and upgrade services Orange County Mori Seiki emergency repair near me Mori Seiki machine diagnostics Orange County Mori Seiki CNC service specialists near me

© 2016